Reactor de resina de poliéster insaturado

En la fabricación de polímeros se emplean comúnmente una variedad de reactores de polimerización, incluidos los continuos (por ejemplo, tanques de agitación continua, tren de reactores de tanque de agitación continua y reactores de tipo bucle), discontinuos y semicontinuos. 1000 ~ 80 000L; Presión negativa -0.1 ~ 50bar; Calentamiento de aceite térmico, calentamiento de vapor, calentamiento eléctrico, calentamiento electromagnético, calentamiento de infrarrojo lejano, acero inoxidable SUS304, SS316L, SS310S, 321, acero dúplex 2205, titanio, níquel, circonio o revestimiento de PTFE, Hastelloy C-276, C22, placa de revestimiento.

- hxchem

- porcelana

- 60 días después del pago

- 40 juegos / mes

Detalles

Unsaturated Polyester Resin Reactor

INTRODUCTION

Synthetic polymers are synthesized from monomers by a multitude of reaction mechanisms, including addition and step-growth reactions, and polymerization processes (e.g., bulk, solution, precipitation, suspension, emulsion, solid catalyzed polymerization, and interfacial polycondensation). Their macromolecular architecture (e.g., molecular weight distribution, copolymer composition distribution, and branching distribution) depends not only on the chemical nature of the monomers, type of polymerization mechanism, and physical state of the polymerization system but also on the reactor configuration. A variety of polymerization reactors, including continuous (e.g., continuous stirred tanks, train of continuous stirred tank reactors, and loop-type reactors), batch, and semibatch, are commonly employed in polymer manufacturing.

MAIN SPECIFICATION | |

Type | FCH1000~80,000L |

Volume(L) | 1000~80,000L |

Working pressure(MPa) | Negative pressure -0.1~20 |

Working temperature(°C) | -196~350℃ |

Stirring speed(rpm) | 0~1200 |

Motor power(KW) | 80w~125kw |

Heating power(KW) | 3~90 |

Heating type | Heat oil heating, steam heating, Electric heating, Electromagnetic heating, far-infrared heating, |

Charging type | Charging from above, discharging from bottom. |

Stirring type | Customized propeller, turbine, paddle, anchor, frame, screw belt type. ...etc |

Seal type | Magnetic seal, mechanical seal, |

Motor | General DC motor, DC servomotor or explosion-proof motor according to customers’ requirements. |

Construction materials (Wetted parts) | Stainless steel SUS304, SS316L, SS310S, 321, duplex steel 2205, Titanium, Nickel, Zirconium, or PTFE lining, Hastelloy C-276, C22, cladding plate. |

Other Accessories | Condenser, storage vessel, constant pressure feed tank, receiving tank, thin film evaporator&Short path (molecular) distillation. |

Condensation polymerization releasing small molecules as by-products such as water or methanol. Because this reaction resulting loss of small molecules which is often water, it’s also called dehydration polymerization. Concentrated Sulfuric Acid is used to process to accelerate reaction. Peptide binding and Ester binding is a typical example of condensation polymerization. Ex) polyamide, polyester, urethane, bakelite

Addition Polymerization Addition polymerization is a reaction, where many monomer bond together via rearrangement of bonds without the loss of any monomers. This occur in different ways which may be through free radical polymerization, cationic polymerization, anionic polymerization andcoordination polymerization. Ex) PVC, polyethylene, polystyrene Copolymerization Copolymerization is a reaction derives polymer from 2 (or more) monomeric species, as opposed to a homopolymer where only one polymer is used. Common examples of this is a rubber using butadiene and styrene. It's widely used in chemical industry and fiber industry. Coordination Polymerization Coordination Polymerization is a reaction in which monomer adds to growing macromolecule through an organometallic active center. Coordination type polymers are also stereoregular and can be isotactic or syndiotactic instead of just atactic. Polymerization Pros and Cons of Polymerization Polymerization used in industry is classified as follow : bulk polymerization, solution polymerization, suspension polymerization, emulsion polymerization. Refer to the following table for properties of each methods.

Product Features

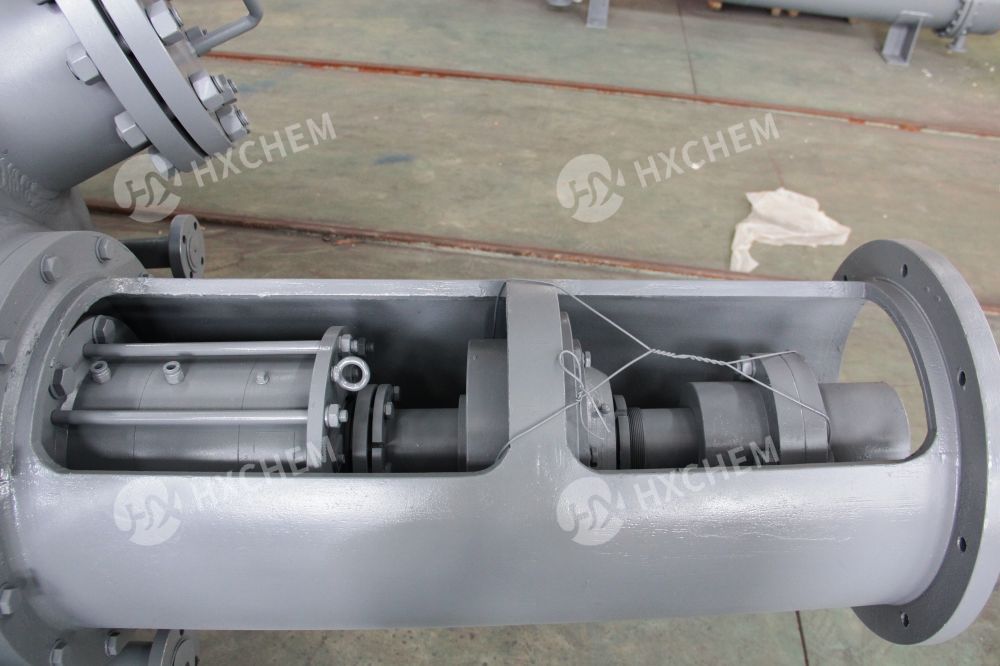

Internal Designing

Customize for You

Agitator

Product Paramenters

Model No. | Vol. (L) | A (mm) | B (mm) | C (mm) |

FCH1000 | 1000 | 1000 | 1100 | 3800 |

FCH2000 | 2000 | 1200 | 1500 | 4200 |

FCH3000 | 3000 | 1400 | 1700 | 4500 |

FCH5000 | 5000 | 1600 | 2150 | 4700 |

FCH6000 | 6000 | 1700 | 2350 | 5300 |

FCH8000 | 8000 | 1900 | 2500 | 5700 |

FCH10000 | 10000 | 2000 | 2800 | 5800 |

FCH15000 | 15000 | 2400 | 2900 | 6100 |

FCH20000 | 20000 | 2600 | 3300 | 7100 |

FCH25000 | 25000 | 2800 | 3550 | 7600 |

FCH30000 | 30000 | 2800 | 4350 | 9100 |

Note: Larger size and specific data will be designed and confrimed according to your requires! | ||||

Customization

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not.

7. Internal cooling coil or not, exchange area?

8. Lifting device or not?

9. Your other requests

......Contact us

We like to help you to accomplish your plans.